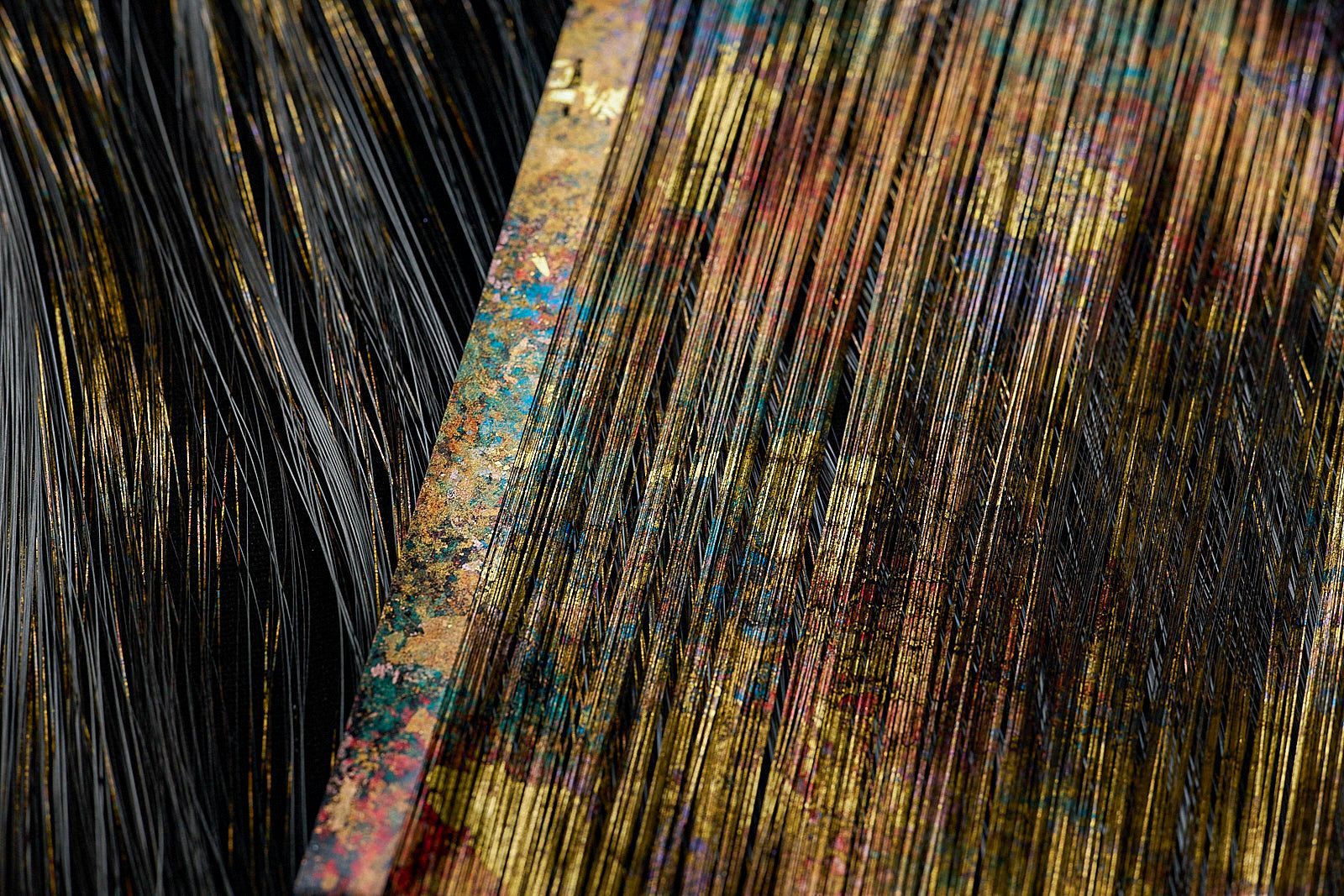

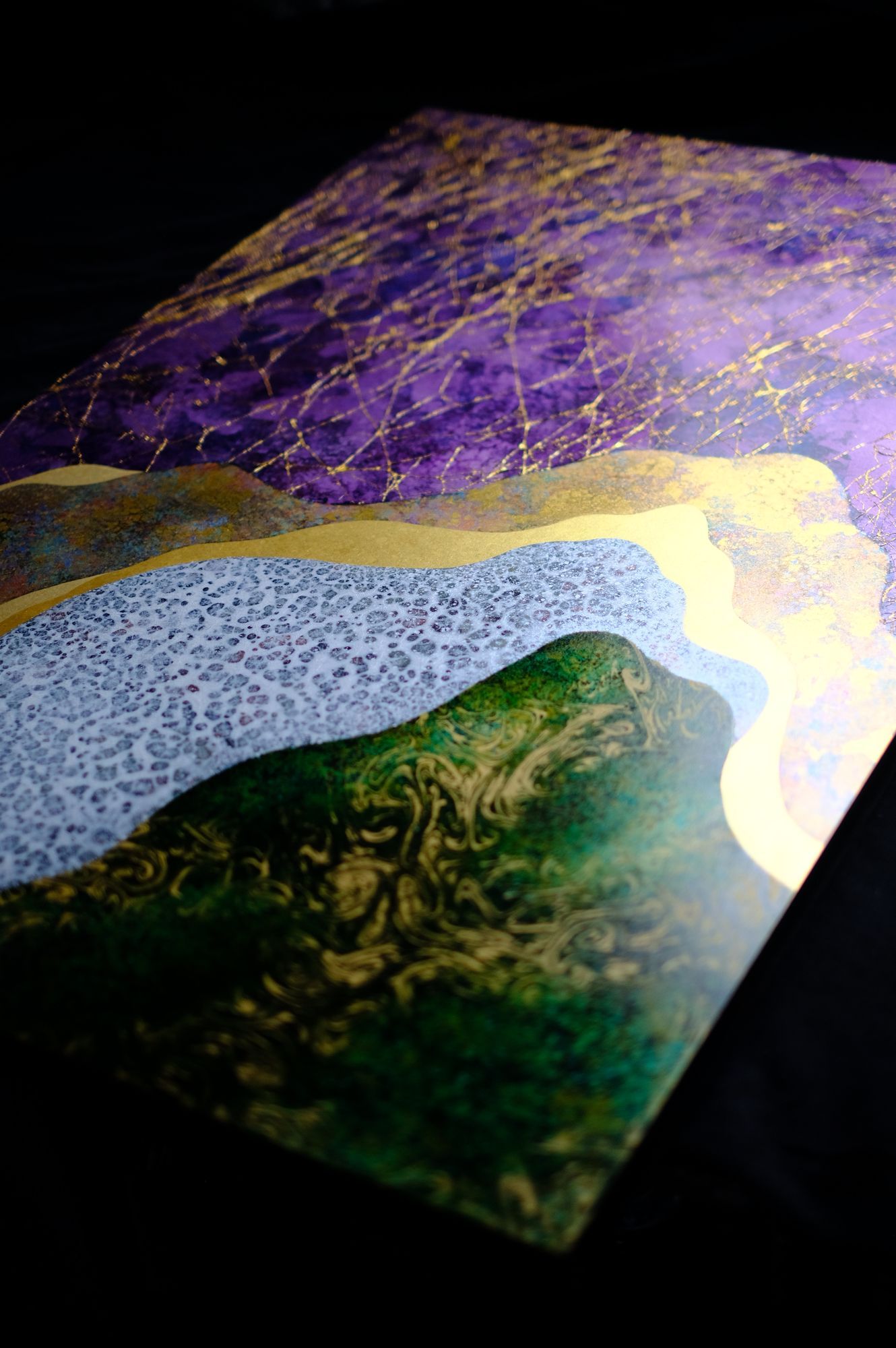

The application of silver leaf at various stages of oxidation to Japanese washi paper in layers creates the illusion of depth. The paper is then sliced into strips of 1/64 inch (.4 mm) and is then woven as a weft into a silk warp. The floral design is then added by embroidery. Therefore, the piece is 50% silk and 50% paper.

CONTACT ・ Kohei MURATA

Website: Rakugeikoubo

Website: Nobegane

Instagram: @koheimurata.9

Japancraft21: Email Us